Exatron / Larsen Associates

Thermal Forcing Test System for Benchtop temperature IC Testing

Handlers Designed and Made in the USA  by Exatron for over 50 years

by Exatron for over 50 years

Home /Pick & Place / Laser Marking / Rotary / Gravity Feed / MEMS / Tape & Reel / Serialization / High UPH / Programmer / Temperature / Contact

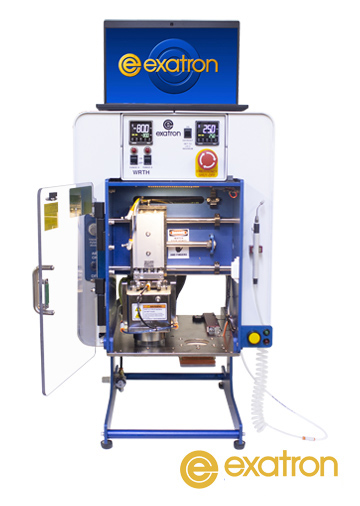

New! Thermal IC Test System

Newto the Market is Exatron's Advanced Designed Refrigeration-Direct-Contact, Thermal Forcing, Temperature Conduction, Heating and Cooling IC testing system. Featuring: -80C to +175C work range with +/- 0.1C control.

- Ideal for RF test applications.

- No Peltiers are used.

- Heat or cool just DUT and test socket.

- No Frost!

- Components at room temperature.

- No forced air used to cause static.

- Wide Range Thermal Head (WRTH) clips on instantly.

- Constant thermal contact to the DUT.

- Cost well below Thermal Stream forced-air systems and with better performance.

The Better IC Thermal Test Solution

Exatron's Direct-Contact Thermal Forcing IC Testing System is ideal when a cheap electronic Peltier type equipment is just not good enough, and when your expensive thermal forced-air thermal stream equipment freezes your board or creates static electricity or is just too much trouble and too expensive for what you get and have to deal with on a frequent basis. Your answer is Exatron's compact unit which can fit under your bench. Exatron's Semi-Automatic Thermal Forcing Test System for your test lab today.

The Frost Free, High Performance, Choice

Exatron's Semi-automatic Thermal Forcing Test System PET-4D is a great new standard of advanced design featuring virtually Frost Free, High Performance, with just middle-of-the-road costs. There are no expensive fluids to buy, spill or contaminate. There are no ESD issues as with forced air or thermal stream air. 3 phase power is not required. There are no tools as the head snaps on and off quickly and easily. The unit features a Windows touch screen laptop interface with great diagnostics and data logs. Cooling power: 60W at -55C. Fast soak times, cut in half.

Direct Contact Conduction Thermal Test

Exatron's proven direct contact conduction thermal forcing IC test method, the Thermal Forcing Test System PET-4D,, is more powerful than electronic Peltier systems and more selective than forced air stream options, with none of the streamed air thermal stream frost or ESD issues. All Exatron thermal forcing test systems and handlers are fully designed and made in the USA by Exatron, since 1974.

Purge Enclosure

The Purge Enclosure surrounds the socket and prevents frost build up. Guaranteeing zero frost during test, Exatron's complete socket purge protection features top and bottom socket gaskets and internal and external purge air jets, which can be controlled as needed via the convenient touch screen interface.

Contact Us today

New advanced units are now avaiable.