Aries Electronics / Larsen Associates

Test Sockets, Burn-In Sockets, IC Adaptors, Display Sockets, plus Standard & Custom Packaging Solutions

Test Sockets, Burn-In Sockets, IC Adaptors, Display Sockets, plus Standard & Custom Packaging Solutions

Test & Burn-in Sockets / IC Adapters "Correct-A-Chip™"/ High Temperature Sockets / Display Sockets / Contact US

Aries Electronics:

Test Sockets And / Or Burn-in sockets:

Lots of variety and built to suit your needs.

- Spring Probe Sockets

- For Test: 1GHz up to 18.5 GHz

- For Burn-in: -55C to +150C.

- Package sizes: from 1 millimeter up to 55 mm

- Guaranteed perfect fit and contact.

- Any Pitch

- Any Footprint configuration

Packages:

- ANY SMT Device:

CSP, BGA, micro BGA, Bump-Array, QFN, QFP, MLF, DFN, SSOP, TSSOP, TSOP, SOP, SOIC, LGA, LCC, PLCC, TO and any other

- Any pitch from 0.2mm and up

- Any configuration

- No tooling

- No extra extra lead-time

- Performance and perfect fit Guranteed

- Lower cost

Email us today: Send a device drawing and let us know how many sockets you need, there is no minimum quantity. Contact us today

IC Test Sockets And / Or IC Burn-in sockets:

IC Test Sockets and / or IC Burn-in Sockets any device fooprint

Aries Electronics offers a family of Test Sockets & Burn-in sockets. These spring probe sockets function equally well as either Test Sockets and / or Burn- in sockets. For test, frequency range is from less than 1GHz up to 18.5 GHz and for Burnin the sockets also operate at Burn-In temperatures of -55C to +150C. The same socket with the same footprint can be used for bench test, production test, and burn-in. With or without a removable lid the sockets can be used in automatic some handlers also.The family of 5 tests sockets will accept a range of devices from less than 1 millimeter up to 55 mm all using standard molded bodies, with only the interior protion of the socket customized for your exact device for a guaranteed perfect fit and contact.

- You get all this performance and perfect fit regardless of device and footprint, for the lower cost of molded sockets vs fully machined sockets, which we also provide when required.

Spring Probes for Aries IC Test sockets

Aries Test and / or Burn-In sockets are for CSP, BGA, micro BGA, Bump-Array, QFN, QFP, MLF, DFN, SSOP, TSSOP, TSOP, SOP, SOIC, LGA, LCC, PLCC, TO and any SMT package style made. Also can be compatible with PGA packaged devices and even some through hole devices.

Aries unique universal socketing system allows the socket to be easily configured for any package, on any pitch (or multiple pitch, or staggered pitch, partially populated pitches, any pitch) from 0.2mm or and up, in any configuration, with little or no tooling charge and no extra extra lead-time.

Email today, send a device drawing and let us know how many sockets you need, there is no minimum quantity. Contact us today

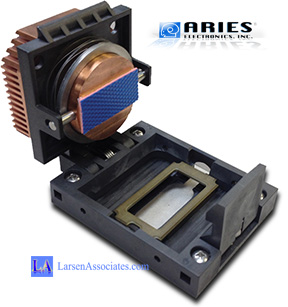

Open top, open access, hole in lid, screw down lid IC test socket options include heatsink or solid top or other requirement that suits your needs.

F

A custom Failure Analysis ic test socket with lens or no lensoptions

Aries Clamshell Optical Access test socket, with or without a lens. Any SMT including CSP BGA or LGA device.

t

t

IC surface mount smt test socket with adapter to through hole plus pin translations

Custom breakout board test fixture with IC test socket from Aries

Typical Vented, air flow, thermal, IC socketwith top hole & side vent slots

Typical top side heat sink custom made to suit your needs from Aries

Typical bottom side heat sink ic test socket with fan.

Typical IC test socket with RTD, Heater, and heatsink for temperature controlled applications

Typical bottom side spring loaded heat sink and fan Aries

Small IC test socket with bottom side heatsink and optional fan

Heat Slug

Cooling tower thermal IC Test socket

Got a "BIG" Thermal issue ;-)?

Or small heat issue? Contact us today!

Thermal Heat Sink sockets top side and bottonm side heatsinks, fans, cooling towers. heat slugs, etc.. Aries can generate Thermal Analysis reports for you.

Adjustable Z IC test and burn in socket for very thin or delicate devices or for device with variable thickness

Quote Request

Data Sheets & Test Reports

Gallery of images with detailed information

Contact Us

1/24/24